Electric vehicles have reached a tipping point. Adoption is accelerating, charging networks are expanding, and governments worldwide are pushing toward zero-emission transport. Yet despite this momentum, EVs still face a familiar set of challenges: limited range, long charging times, safety concerns, and high battery costs. At the center of all these issues lies one component, the battery.

For years, lithium-ion technology has powered everything from smartphones to electric cars. But as EVs scale globally, the limitations of lithium-ion batteries are becoming harder to ignore. This is where solid-state batteries come into focus, frequently seen as a transformative evolution in electric vehicle battery technology.

Honda’s recent progress in solid-state battery development stands out not because it promises overnight transformation, but because it focuses on something far more difficult: real-world production. Rather than chasing lab-only breakthroughs, Honda is laying the groundwork for batteries that can actually be manufactured at scale. This approach could mark a turning point not just for Honda, but for the entire EV industry.

The Problem with Today’s Lithium-Ion Batteries

Lithium-ion batteries have been remarkably successful, but they were never designed with mass-market electric vehicles in mind. As EVs demand higher energy output, faster charging, and longer lifespans, the cracks in current battery technology are becoming more apparent.

One of the biggest limitations is energy density. Lithium-ion batteries can only store so much energy within a given size and weight. To increase range, manufacturers must add larger battery packs, which increases vehicle weight, cost, and complexity.

As lithium-ion batteries rely on liquid electrolytes, they are vulnerable to thermal runaway, a chain reaction that can lead to fires under extreme heat, damage, or manufacturing defects. While rare, such incidents are difficult to control and damage consumer confidence. Faster charging creates more heat, which can shorten a battery’s lifespan. This forces automakers to limit charging speeds to protect long-term durability.

Finally, cost and supply chain pressure remain persistent issues. Lithium-ion batteries depend on materials that are expensive, geopolitically sensitive, and difficult to scale sustainably. These constraints make it harder to reduce EV prices to levels comparable with internal combustion vehicles.

What Is a Solid-State Battery?

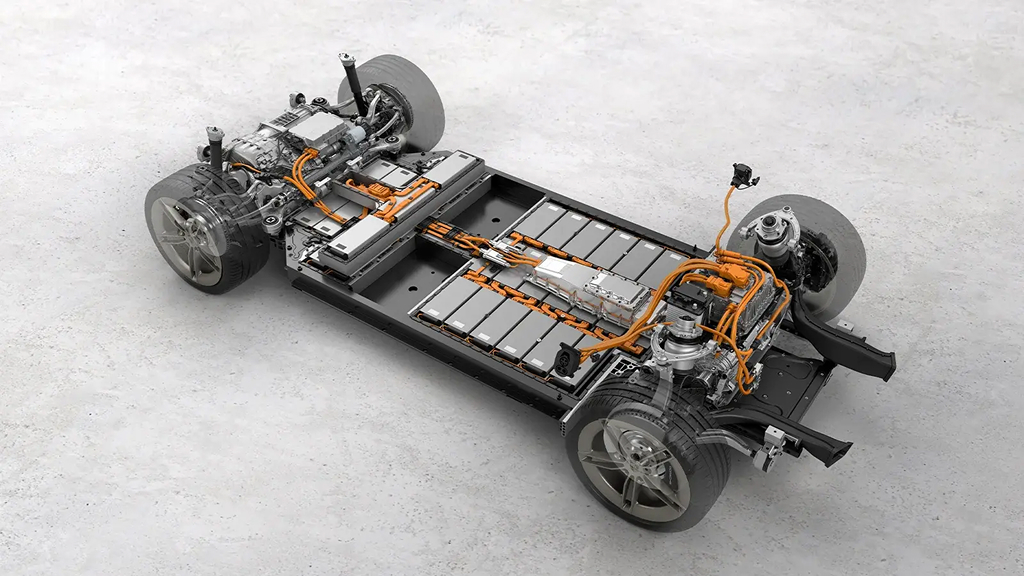

At its core, the difference between lithium-ion and solid-state batteries comes down to the electrolyte, the material that allows ions to move between the battery’s anode and cathode. Traditional lithium-ion batteries use a liquid electrolyte, which facilitates ion movement but introduces risks related to heat, leakage, and instability. Solid-state batteries replace this liquid with a solid electrolyte, fundamentally changing how the battery operates.

This solid structure offers several advantages. First, it allows for higher energy density, meaning more energy can be stored in a smaller, lighter package. Second, solid electrolytes are far more resistant to heat and physical damage, significantly improving safety. Third, the design enables faster ion movement under controlled conditions, opening the door to quicker charging times.

Liquid electrolytes prioritize flexibility, while solid electrolytes prioritize control and stability. The difficulty of maintaining that control at scale is why solid-state batteries have remained experimental for so long.

Honda’s Approach: What Makes It Different

Honda’s solid-state battery strategy stands out not only for its technical goals, but for its strong focus on practical manufacturing. While many companies have demonstrated promising solid-state cells in laboratories, Honda is focused on building batteries that can survive the harsh realities of automotive use.

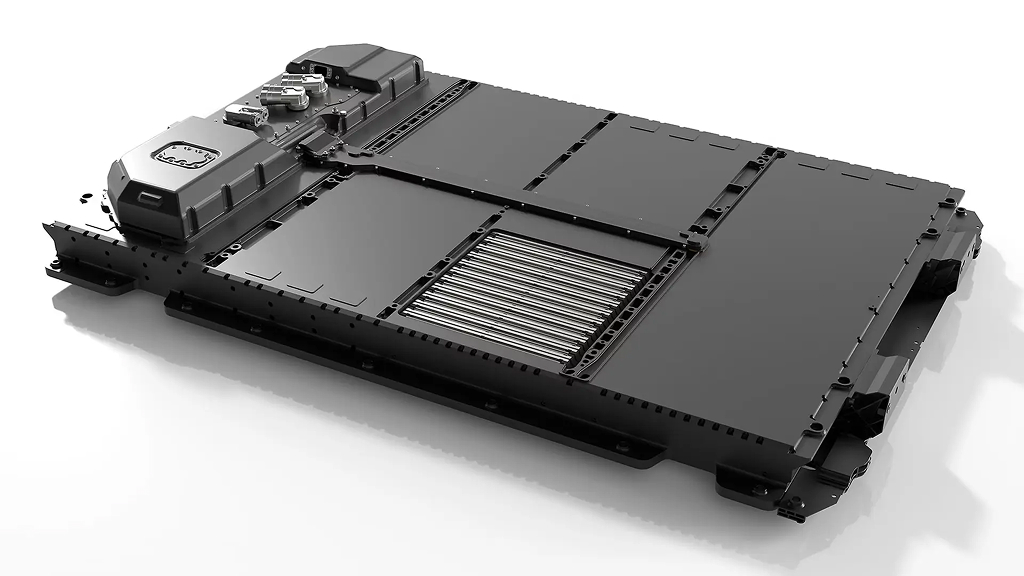

Central to this effort is Honda’s dedicated solid-state battery pilot production line. This facility is designed to replicate real-world manufacturing conditions, allowing engineers to test materials, assembly methods, and quality control processes long before mass production begins.

Rather than optimizing for record-breaking energy density alone, Honda is prioritizing durability, consistency, and scalability. Automotive batteries must perform reliably across thousands of charge cycles, extreme temperatures, and varying driving conditions, standards far more demanding than consumer electronics.

Honda is also developing these batteries in-house, ensuring tighter integration between battery design and vehicle architecture. This approach allows Honda to rethink everything from vehicle weight distribution to thermal management systems, rather than simply swapping one battery type for another. In an industry often driven by bold announcements, Honda’s measured, production-focused strategy stands out as both cautious and credible.

Key Technical Breakthroughs Honda Has Achieved

While Honda has not disclosed every technical detail, several key advancements define its progress in solid-state battery development.

1. Improved Solid Electrolyte Stability

One of the biggest hurdles in solid-state battery development is maintaining electrolyte stability over time. Honda has made progress in developing solid electrolytes that resist cracking and degradation, even after repeated charging cycles, which is critical for long-term automotive use.

2. Lower Internal Resistance

Honda’s battery design focuses on reducing internal resistance within the cell. Lower resistance allows ions to move more efficiently, improving energy transfer while minimizing heat generation during charging and driving.

3. Enhanced Cycle Life

Unlike many early solid-state designs that lose performance quickly, Honda’s approach emphasizes durability. The company is working toward batteries that can endure thousands of charge and discharge cycles without significant capacity loss.

4. Reduced Mechanical Stress and Swelling

High-density batteries often suffer from expansion and structural stress over time. Honda has addressed this by refining cell architecture to maintain physical stability, which helps preserve performance and safety throughout the battery’s lifespan.

5. Automotive-Grade Reliability Testing

Beyond laboratory performance, Honda is testing its solid-state batteries under real-world automotive conditions, including temperature extremes and long-term usage scenarios. This focus ensures the technology meets the rigorous demands of everyday driving.

What This Means for EV Performance

Honda’s progress with solid-state batteries translates into meaningful improvements in how electric vehicles perform in everyday use. Instead of delivering a single headline improvement, the technology enhances multiple aspects of the EV driving experience simultaneously.

1. Longer Driving Range

Solid-state batteries can store more energy within a smaller and lighter package compared to conventional lithium-ion batteries. This allows EVs to travel farther on a single charge without increasing battery size or vehicle weight, reducing range anxiety and making electric cars more suitable for long-distance travel.

2. Faster and More Consistent Charging

Improved thermal stability enables solid-state batteries to handle higher charging speeds with less heat buildup. Lower heat reduces stress on the battery during fast charging, allowing quicker top-ups while helping preserve long-term battery health.

3. Improved Safety and Thermal Stability

By eliminating flammable liquid electrolytes, solid-state batteries significantly reduce the risk of overheating and fire. This added safety margin enhances vehicle reliability and could simplify cooling systems, improving overall system efficiency.

4. Reduced Battery Degradation Over Time

Solid-state designs are less prone to the wear and chemical breakdown that affect lithium-ion batteries. As a result, EVs can retain their driving range and performance more effectively over years of use, improving long-term ownership value.

5. Lighter Vehicles and Better Efficiency

Higher energy density allows manufacturers to use smaller battery packs, reducing overall vehicle weight. Lighter EVs consume less energy, improve handling, and deliver a more responsive driving experience.

6. Greater Design Flexibility for Automakers

Compact battery structures give automakers more freedom in vehicle design. This flexibility can translate into improved cabin space, better weight distribution, and new EV architectures optimized around solid-state technology.

7. Lower Long-Term Ownership Costs

Improved durability, slower degradation, and enhanced safety can reduce maintenance and replacement costs over time. Together, these factors contribute to a lower total cost of ownership for EV buyers.

Manufacturing and Cost: The Real Challenge

Despite their promise, solid-state batteries face formidable manufacturing hurdles. Producing solid electrolytes with consistent thickness and defect-free structure is far more complex than handling liquids. Even microscopic flaws can impact performance and reliability.

Cost is another significant obstacle. Early solid-state batteries are expensive due to specialized materials and low production volumes. Achieving cost parity with lithium-ion batteries will require years of refinement and economies of scale.

Honda’s strategy addresses these challenges head-on. By investing early in production processes, automation, and yield optimization, Honda aims to reduce costs gradually rather than relying on theoretical breakthroughs.

This realism is crucial. Without scalable manufacturing, even the most advanced battery technology remains commercially irrelevant.

When Will Honda’s Solid-State EVs Arrive?

Honda has indicated that solid-state batteries are targeted for commercial deployment later this decade. However, this does not mean an immediate industry-wide rollout. Initial applications are likely to appear in limited-volume or premium models, where higher costs can be absorbed more easily. As production processes mature and costs decline, broader adoption will follow.

It is also important to distinguish between pilot production and mass-market availability. While prototypes may appear earlier, large-scale deployment will depend on manufacturing readiness and supply chain stability. In short, Honda’s timeline reflects caution rather than delay, an approach consistent with the complexity of the technology.

How Honda Compares to Toyota, Nissan, and Other Rivals

Honda is not alone in pursuing solid-state batteries. Toyota has invested heavily in the technology for years, while Nissan and several startups are exploring alternative approaches. What differentiates Honda is its manufacturing-first mindset. While some competitors emphasize early demonstrations or aggressive timelines, Honda appears focused on reducing the gap between research and production.

This diversity of strategies benefits the industry as a whole. Different solutions may coexist, and breakthroughs in one approach often accelerate progress across others. Rather than a race with a single winner, solid-state battery development is shaping up to be a collective evolution.

Broader Impact on the EV Industry

If Honda succeeds, the implications extend far beyond a single brand. Solid-state batteries could reshape EV design, reduce dependence on current battery chemistries, and accelerate the transition to electric mobility.

Improved safety could also influence future regulations and insurance models for electric vehicles. Faster charging could reduce pressure on charging infrastructure. Higher efficiency could lower the environmental footprint of EV production. Perhaps most importantly, success from a legacy automaker like Honda signals that solid-state batteries are moving out of the lab and into the real world.

Honda’s solid-state battery breakthrough represents more than a technological milestone, it reflects a shift in how the EV industry approaches innovation. By prioritizing manufacturability, safety, and long-term reliability, Honda is addressing the hardest problems first.

While solid-state batteries will not replace lithium-ion technology overnight, Honda’s progress brings that future meaningfully closer. For EV buyers, it promises longer range, faster charging, and greater peace of mind. For the industry, it offers a credible path beyond today’s limitations. In the race toward electrification, Honda’s quiet, methodical approach may prove to be one of the most impactful.